Heggli & Gubler is one of the high-tech players in the metal spinning sector. We supply a large proportion of our products to the aeronautics, electrical, biotechnology, chemical and process industries. Within this context, we process materials such as chromium-nickel steels, Hastelloy or Inconel for turbine construction and, of course, all conventional metals as well. We invest continually in new production facilities and continually develop the expertise of our employees.

Production techniques

- Metal spinning

- Deep drawing

- Punching

- Welding

- Turning

- Milling

- Grinding

Metal Spinning

Anything round is clearly a job for Heggli & Gubler AG. Whether the part you need is small or large, we can meet your requirements with our extensive machinery. As one of the leading companies for metal spinning services, we are the right partner for you – from prototypes and custom one-off items right through to entire series.

Deep drawing

Our deep drawing press has a maximum capacity of 300 tonnes and is ideal for use in combination with and as an addition to metal spinning. The drawing press can be used not only for small and large batch production but also for individual prototypes and custom products. Our drawing press creates drawn parts of the utmost quality.

Punching

Our eccentric punches are vital for providing additional services for our metal spun parts. From holes and punched patterns through to special contours, our eccentric presses are always the perfect option. With capacities ranging from 40 to 100 tonnes, we can accommodate a wide range of preferences and requirements.

Welding

Welding has become one of the most important additional services offered by Heggli & Gubler AG, as many spun metal parts require further processing and have to be provided with flanges and piping. Our welding installations are state-of-the-art and are constantly being adapted in line with customer requirements.

Turning

At Heggli & Gubler AG, turning is used for various purposes – firstly, for making metal spinning tools and, secondly, for pre-machining, finishing and further processing spun metal parts. We use both conventional lathes and CNC machines for this.

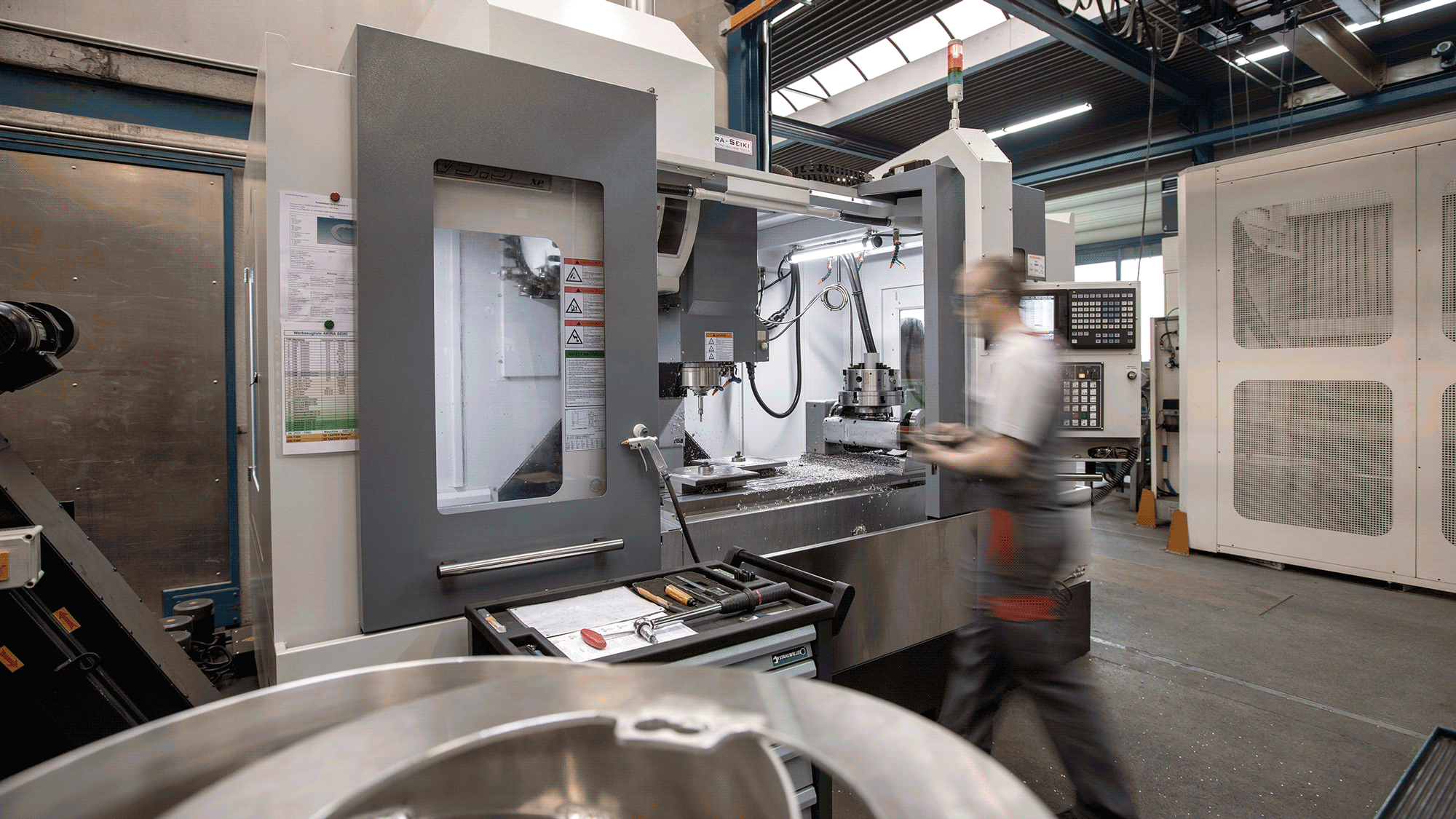

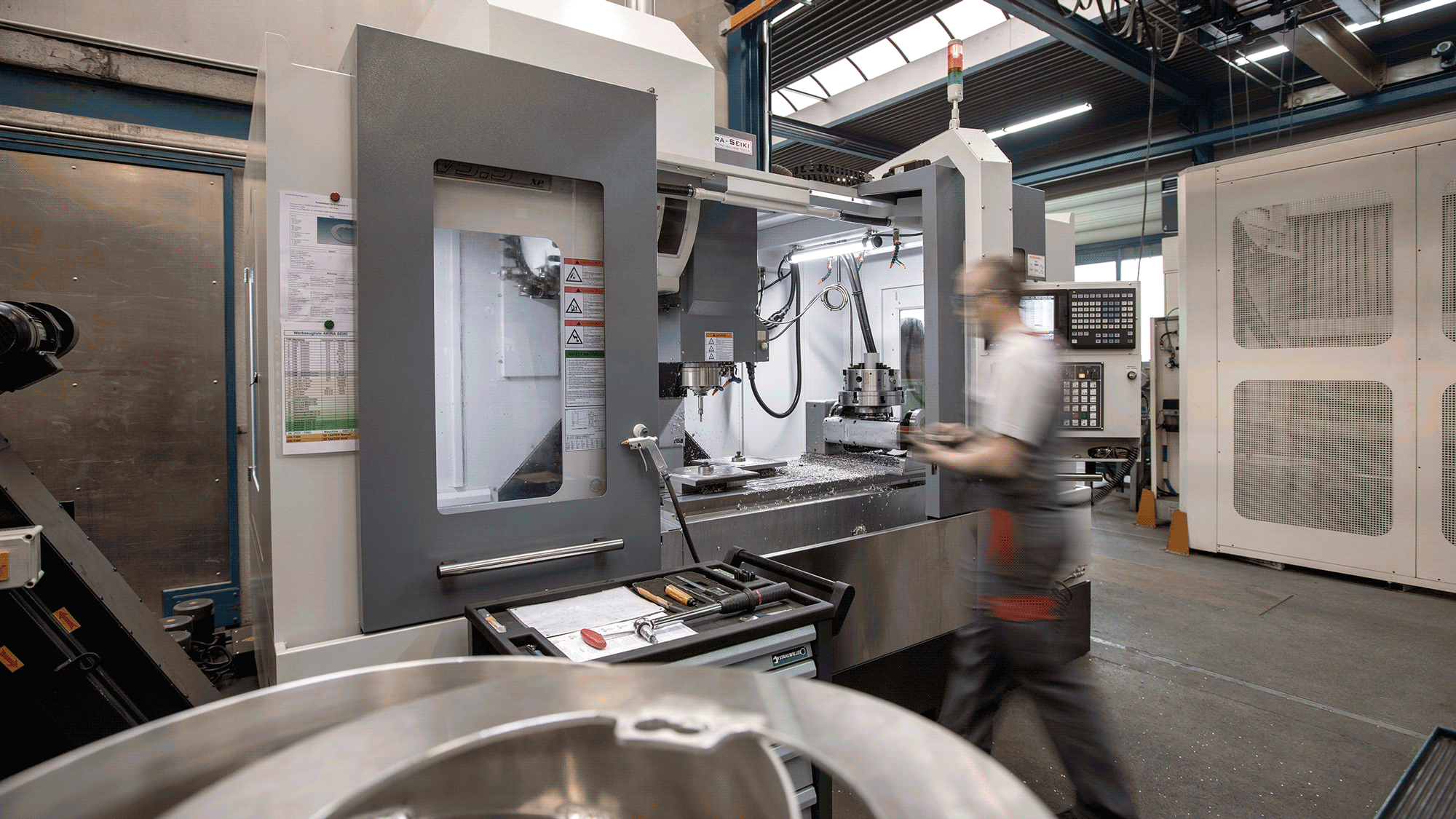

Milling

For the machining of metal spun parts, we rely on our modern four-axis machining centre.

- 3-axle machine for jobs involving sizes up to 2,000 x 800 x 800 mm

- 4+1-axle simultaneous machine for jobs involving sizes up to 1,350 x 640 x 660 mm

Grinding

At the finishing stage, any sharp edges, welding seams and unevenness on the metal spun parts are ground by machine or hand to create a smooth result.

in Germany

in Germany